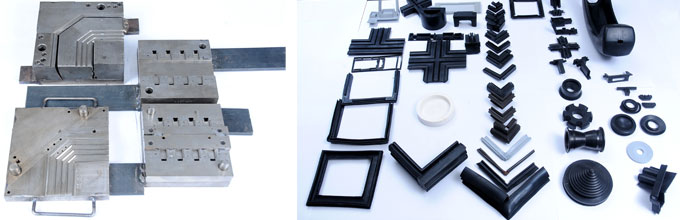

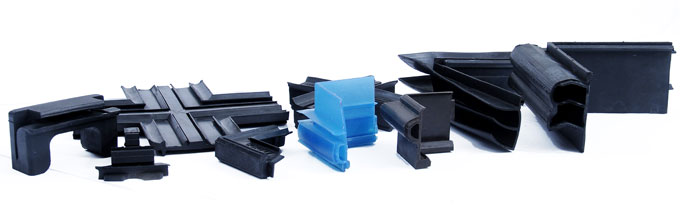

Rubber Moulded Parts

IRC Moulded Rubber Products comprise wide range of Polymer use, i.e. EPDM, Neoprene, Nitrile, SBR and NR. Compounding is done to meet relevant BS, DIN and ASTM Standards to achieve best performance.

Production of Rubber Moulded Products is done by Compression and Transfer Moulding process followed by automatic Deflashing.

In the Transfer Moulding process rubber compound is transfered under pressure into the mould cavity and allowed to fill the cavity obtaining the shape of the mould and cross-linked by using the platen temperature, finally product is formed in the required shape. In compression Moulding process compound is pressed under sufficient hydraulic pressure to obtain mould cavity shape and compaction while curing process in progress.

General Physical Properties

| Properties | Specifications | Test Method |

|---|---|---|

| Tensile Strength | 10.5 MPa Min | ASTM D412 |

| Elongation at Break | 300 % min | ASTM D412 |

| Hardness (Shore A) | 65 – 75° A | ASTM D2240 |

| Compression Set | 25 % Max | ASTM D395 |

| Accelerated Aging Decrease in Tensile Strength Decrease in Elongation |

15% 20% |

ASTM D573 |

| Ozone Resistance 100PPM for 96 Hrs at 20% Stretch at 40° C | No cracks when seen at 10X magnification | ASTM D1149 |

| Joint Strength | To Withstand 100% Elongation and 180 Rotation without any visible sign of separation | ASTM C 443M |