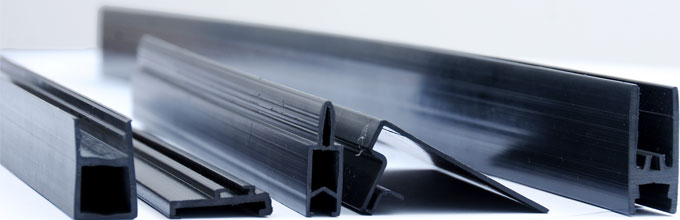

PVC extruded profiles are widely used in the following areas;

- Construction Industry because it is cheap, durable, and easy to assemble

- Clothing, Upholstery, electrical cable insulation by making the PVC softer and flexible by adding plasticizers

- Window partition

- Glaze Bead Section

- Automotive Industry

- Refrigeration and Air-condition Industry

- Electrical Industry

- Furniture Industry

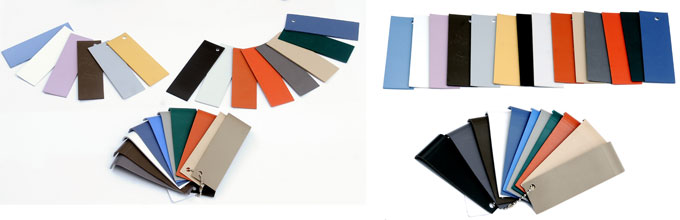

Various shapes and sizes of PVC profiles are introduced and manufactured depending upon the designer’s choice and innovations for building industry. IRC is the leader in the Middle East in developing PVC profiles in a shortest development time of any intricate shape that customer requires. It is available in so many colors depending on customer specific requirement.

Quality of PVC profiles is monitored at certain intervals during extrusion. It hardly varies in our strictly monitored process where size, shape, dimensional accuracy and appearance matters in IRC culture. Fit and function is verified at certain intervals and packed in certain meters of length in customized IRC lebelled carton boxes where stickers can let know the whole information for traceability for customer’s feedback on any discrepancies. PVC material is procured from approved supplier whose materials are pre tested and supplied in lot. However a physical property of final product is finally checked at IRC lab for each lot and recorded which can be traced for a period of at least 6 months.

| Properties | Specifications | Test Method |

|---|---|---|

| Hardness (Shore A°) | 70° | BS 903 |

| Specific Gravity (g/cm3) | 1.03 | BS 903 |

| Elongation @ Break % | 360% | BS 903 |

| Tensile Strength (MPa) | 5.1 | BS 903 |

| Compression Set (%) 24 Hrs @ 25° C | 25% | BS 903 |

| Weather resistance | Good | BS 903 |