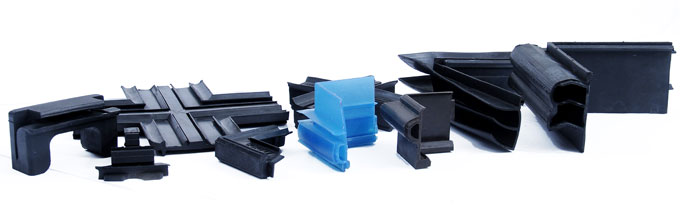

Vulcanized EPDM Corner Jointed Gaskets and Vulcanized Picture Frame Gaskets offer excellent corner Sealing against water and dust seepage and provide good thermal insulation for cost saving on air conditioning. The corner is the weakest point in the Aluminium System as all Sections are cut and matched to obtain desired angle. The joint is thus prone to allow water seepage due to gap between joint profiles. The vulcanized corner jointed EPDM Rubber gaskets provide perfect Sealing to such joints and avoid needs to fill sealant. Thus a clean performing joint is achieved.

The modern method of producing complex profiles with corner joints involves:

1. Production of accurate profiles in a continuous vulcanizing line.

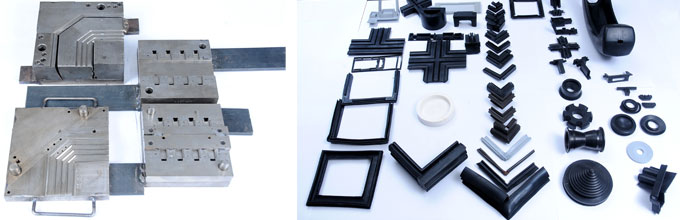

2. Moulding of corners and joining of profile ends to make a complete gasket frame by Transfer Moulding techniques.

In this process the desired profile is Extruded, Cured and before Moulding of corners is cut to controlled length using a cutting gauge.

In the Transfer Moulding process the profile geometry is matched to the moulded corner/end requirements. Rubber compound is injected under pressure into the mould cavity and allowed to vulcanize, obtaining the shape of the mould and cross-linking the profile edges to the moulded jointed area. Thus a continuous and homogeneous gasket is formed.

| Properties | Specifications | Test Method |

|---|---|---|

| Tensile Strength | 10.50 MPA Min | BS 903; Part A2 |

| Elongation Break | 200 % Min | BS 903; Part A2 |

| Hardness Shore Aº | 55 – 65 | BS 903; Part A26 |

| Compression Set | 25 % Max | BS 903; Part A6 |

| Accelerated Aging Decrease in Tensile Strength Decrease in Elongation |

15 % 20 % |

BS 903; Part A2 BS 903; Part A2 |

| Ozone Resistance 100 PPM 96 Hrs 20% Stretch 40° C | No cracks when seen at 10X magnification | BS 903; Part A43 (Specimen A) |

| Joint Strength | To Withstand 100% Elongation and 180° Rotation without any visible sign of separation | ASTM C 443M |